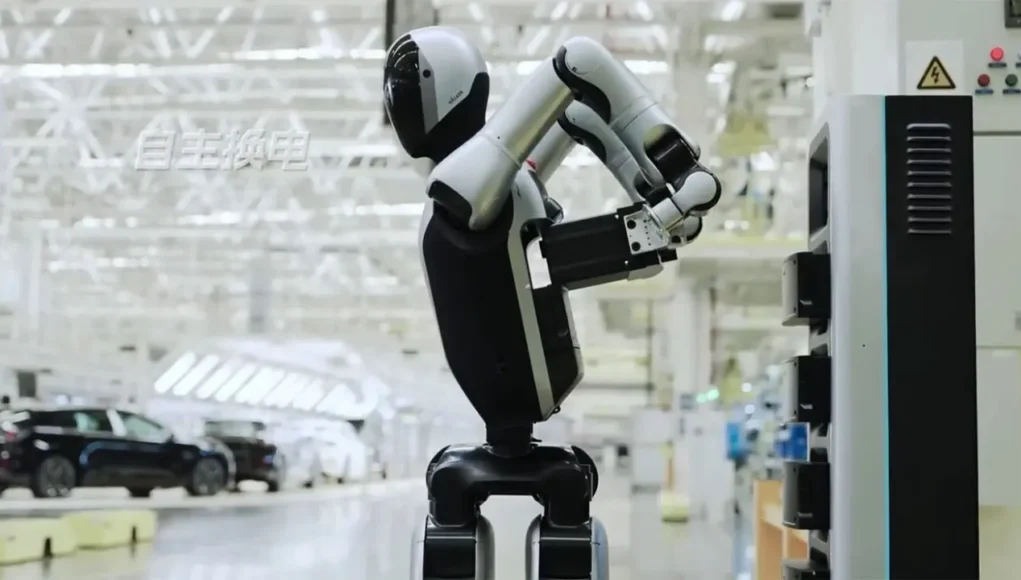

A groundbreaking development from China is set to disrupt the robotics industry: UBTech, a leading Chinese robotics company, has unveiled the Walker S2, an insanoid robot capable of autonomously replacing its own battery. This innovation allows the robot to manage its energy needs entirely without human intervention, ensuring uninterrupted operation in industrial environments.

Walker S2: A Glimpse into Self-Sustaining Robotics

During its demonstration, the Walker S2 showcased its ability to swap out its battery and insert a fresh one in just three minutes. This seamless process involves the robot independently navigating to a charging station, removing the depleted battery, inserting a fully charged replacement, and then resuming its tasks.

Designed specifically for continuous service in demanding industrial settings, the Walker S2 features a dual battery system. Should the primary power source encounter an issue, the secondary battery seamlessly activates, preventing any energy disruption and ensuring the robot continues its work. This intelligent system also enables the robot to strategically decide its energy approach: depending on the urgency of its current task, the Walker S2 can autonomously choose between recharging or performing a full battery swap.

BrainNet: The Collective Intelligence of UBTech’s Walker Series

This self-charging capability isn’t UBTech’s only recent advancement. Earlier this year, the company announced collaborative versions of its Walker series robots. Notably, Walker S1 robots deployed in Zeekr’s 5G-enabled smart factory operate in sync with UBTech’s “BrainNet,” a cloud-backed artificial intelligence system. BrainNet bestows a “shared mind” upon the robots, fostering collective intelligence.

In this system, a central “super brain” oversees decision-making and planning for the production line, while “sub-brains” respond to real-time production changes and coordinate task distribution among the robots.

The AI underpinning these systems is powered by a large-scale model equipped with multimodal reasoning capabilities. UBTech’s DeepSeek-R1 model, specifically trained on data from the automotive industry, allows the robots to perform tasks such as assembly, quality control, and material handling with both speed and high precision. Unlike their previous generation, Walker S1 robots now operate as a team, seamlessly integrating different production steps.

The Future of Industrial Robotics

The new systems introduced by UBTech underscore a significant shift in industrial robotics. Robots are no longer merely performing mechanical tasks; they are now actively involved in energy management and task coordination. This evolution promises to boost efficiency and autonomy in manufacturing and beyond.

What do you think is the most impactful aspect of robots being able to manage their own power?